Clock Selection

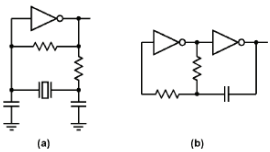

The majority of clock sources for microcontroller can be grouped into two types: those based on mechanical resonant devices, such as crystals and ceramic resonators, and those based on electrical phase-shift circuits such as RC (resistor, capacitor) oscillators. Silicon oscillators are typically a fully integrated version of the RC oscillator with the added benefits of current sources, matched resistors and capacitors, and temperature compensation circuits for increased stability. Two examples of clock source are illustrated in the following figure. Figure (a) shows a Pierce oscillator configuration suitable for use with mechanical resonant device like crystals and ceramic resonators, while figure (b) shows a simple RC feedback oscillator.

The various clock sources are compared below:

The various clock sources are compared below:

| Clock Source | Accuracy | Advantages | Disadvantages |

| Crystal | Medium to High | Low Cost | Sensitive to Electromagnetic interface(EMI), vibration and humidity. Complex circuit impedance matching. |

| Crystal oscillator Module | Medium to High | Insensitive to EMI, vibration and humidity. No additional components or matching issues. | High cost, high power consumption, sensitive to vibration, large packaging. |

| Ceramic resonator | Medium | Lower Cost | Sensitive to EMI, Vibration and Humidity. |

| Integrated Silicon Oscillator | Low to Medium | Insensitive to EMI, vibration, and humidity. Fast startup, small size, and no additional components or matching issues. | Temperature sensitivity is generally worse than crystal and ceramic resonator types; high supply current with some types. |

| RC Oscillator | Very Low | Lower Cost | Usually sensitive to EMI and humidity. Poor temperature and supply-voltage rejection performance |

We used Crystal for Pratham.

If you are done reading this page, you can go back to Electrical Subsystem