Anodizing

Contents

Introduction

Anodizing is an electrolytic passivation process which is used to increase the thickness of the natural oxide layer on the surface of metal parts.

Applications of Anodizing

- Anodizing increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal does.

- Anodic films can also be used for a number of cosmetic effects, either with thick porous coatings that can absorb dyes or with thin transparent coatings that add interference effects to reflected light.

- Anodizing is also used to prevent galling of threaded components.

Why Anodize?

Black inorganic anodized aluminium alloys are used for managing passive thermal control on spacecraft and for avoiding stray light in optical equipment.

Due to the vacuum of space, thermal regulation of satellites is passively managed by radiative exchange between its external surfaces and the environment. Satellite temperatures in a space environment are often passively controlled by thermal properties of suitable surfaces, i.e. having convenient solar absorptance (α) and emittance (ε).

The feature of black coatings is that their α/ε ratio is close to one, which allows passive thermal control of equipment by effectively transferring the heat via radiation.

Black anodic films (α > 0.93 ; ε > 0.90) including inorganic dyes are mainly used because of their low cost, their corrosive and wear resistances during storage, as well as the low risk of contaminating the spacecraft’s instruments, especially by outgassing.

The anodic film is developed by electrochemical oxidation of the metal surface, without addition of any substances. From this point of view, the anodic film is not a coating, but a conversion interface tightly bound to the metallic substrate.

A four-digit numerical designation system is used to identify wrought aluminium and aluminium alloys. The first digit of the four-digit designation indicates the group.

Aluminium > 99.00 %—1XXX.

Aluminium alloys grouped by major alloying element(s);

Copper—2XXX;

Manganese—3XXX;

Silicon—4XXX;

Magnesium— 5XXX;

Magnesium and Silicon—6XXX;

Zinc—7XXX;

Other elements—8XXX;

Unused series—9XXX.

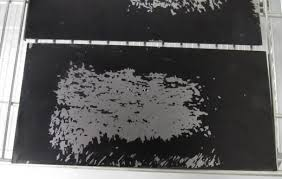

In 2005, an alert from the European Space Agency (ESA) mentioned many cases of particle detachment from black anodic films, supported especially on 2XXX and 7XXX type aluminium alloys, after three thermal cycles. Such particle pollution is very hazardous for the lifetime of the satellite, potentially inducing the disturbance of any optical or mechanical mechanisms.

Mechanical Behavior and Defects

The anodizing process is an electrochemical conversion of the metal surface and does not involve the addition of external material. That is the reason why anodic films are considered sufficiently adherent for the usual applications. The coloured sealed films are studied from the mechanical point of view, before and after thermal cycling. This cycling simulates the space environment, potentially inducing internal stress, cracking and ultimately flaking of the coatings.

Cracking

Due to the difference of thermal expansion coefficient between the anodic film and the substrate, heating induces tensile stresses in the coating that can lead to cracking if the fracture limit is reached.

Flaking

The major risk for space applications is not simply the cracking of the surface layer but flaking, because the particles released could settle on cold parts, typically mirrors, lenses or mechanisms.Then the satellite instruments would be damaged decreasing the mission’s lifetime. In addition, a high level of flaking could change the thermo-optical properties of the surface affecting thermal control. Flaking is generally observed on parts that had been thermally cycled. The loss of adhesion is revealed for example on pulling off tapes used to fix thermocouples to the surface during thermal cycles.

Crazing

Anodized finishes will craze (crack) when the aluminum substrate is deformed in any fashion. This happens because the base aluminum has a marginal degree of elasticity, while the anodized coating has virtually no elasticity. When the part is bent, the aluminum will deflect quite far without failing, but the coating cracks immediately upon deflection.

Testing

In space, satellites are directly lighted by the sun and then pass into the shadow of Earth, causing thousands of thermal cycles during their lifetime. To simulate the space environment, the ESA Standard recommends performing 100 cycles between -100 and 100°C under vacuum which lasts for 5 minutes minimum and a have a slope of 10°C per minute. These conditions are defined for the general case and for all kinds of materials and equipment (from polymers to electronics).

References

- http://www.aacron.com/docs/Crazing%20Caused%20By%20Bending%20and%20Forming%20Operations.pdf

- http://oatao.univ-toulouse.fr/2628/1/Mabru_2628.pdf

- http://www3.ntu.edu.sg/ThinFilms/mae-thinfilms/Thinfilms/pdfpapers/xiaodong.pdf

- https://dir.indiamart.com/impcat/black-anodizing.html

- http://www.electrochempune.com/hard-coat-anodizing.html

- https://www.anoplate.com/finishes/anodizing/

If you are done reading this page, you can go back to Mechanical Subsystem