Crimping

Contents

Introduction

Crimping is joining 2 pieces of metal or other ductile material (usually a wire and a metal plate) by deforming one or both of them to hold the other. The bend or deformity is called the crimp.

Crimping is developed to replace the need to solder terminations, it provides a high quality connection between a terminal and a wire at a relatively low applied cost. The methods for applying crimp terminations depend on the application, volume, and range from handheld devices to fully automated systems.

Without a thorough understanding of the crimping process, and all the factors that can affect it, the result may not meet expectations.

The three key elements in the crimping process are the terminal, the wire, and the tooling.

Terminal

For most applications, it is not economically practical for connector manufacturers to design a terminal to accept one wire size, one wire stranding, and one insulation diameter (UL type) as well as Mil Specification ( United States defense standard, often called a military standard). Most terminals accommodate many wire sizes, stranding, and a range of insulation diameters, and the terminals are designed to meet acceptable levels over this entire range.

Wire

The wire stranding and insulation type can vary widely within one wire size. Wire strands can be copper, tinned, over coated, or top coated. Wire insulation materials, thickness, and durometers vary from application to application.

Additional Information AWG - American Wire Gauge is a standardized wire gauge system used since 1857 predominantly in North America for the diameters of round, solid, nonferrous, electrically conducting wire.

Wires are of two types:

- Solid: Solid conductors consist of just one strand of metal. They are easier to terminate than stranded conductors. They are also mechanically tough and inexpensive. The major disadvantage of solid conductors is their lack of flexibility.

- Stranded: Stranded conductors are composed of multiple metal strands bunched together in any number of configurations. They are much more flexible than solid conductors, and the higher the strand count, the more flexible they are. While this can add some cost, it is essential for any wire or cable that will need to withstand any kind of movement or flexing.

A finely stranded wire improves crimped joint performance. A wire composed of a few strands of larger size will tend to act as a solid wire in the crimp. Some stranded wire crimp configurations are not satisfactory for solid wire. More deformation must be imposed in order to form wire and barrel into a solid mass. On the other hand, finer strands will more readily fill the inside corners of the crimp shape and more evenly distribute the forces of the crimp.

Procedure

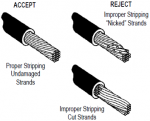

Prepare the Wire

- Check the stranded wire to see if any strands have loosened and expanded to be larger than the wire and the insulation together. If this has occurred, twist the wires to the size they were before they were stripped.

- Check the insulation to ensure that there has been a nice clean cut. Wires with damaged insulation should not be used.

Setup and Operate a Hand Crimp Tool

- Ensure that the hand tool is designed to crimp the size wire and the proper terminal shown on the Hand Crimp Tool Specification sheet.

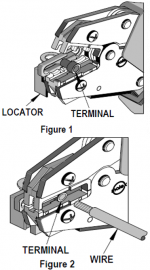

- Place the terminal in the tool.

- If using a locator, lift the locator and insert the terminal in the proper nest with the barrel up and against the locator bar. Release the locator blade to hold the terminal in position.

- Insert the wire.

- Squeeze the handle.

- Inspect for proper crimp location.

Importance of Proper Crimping

Proper attachment of terminal to the wire is critical. Mechanical as well as electrical connections are important - The result of a properly crimped joint is a reliable mechanical and electrical connection.

The mechanical connection is the crimping of the terminal to the conductor. It must be secure enough not to vibrate loose or to be pulled off through normal use.

The electrical characteristics are just as important. The major concern is the amount of electrical resistance caused by the mechanical joint which determines the crimped joint’s ability to conduct current.

One indication of the importance of proper crimping is evidenced in a study for the Space Shuttle Program that traced 28% of all defects to improperly assembled wiring and connectors.

Tips for Crimping

Step 1: Choosing the Wire

Depending on your application, you may or may not have a choice on the wire to use. Firstly do not use solid cored wire, and if you want a reliable job definitely avoid solid wire.

Step 2: Determine the wire size

This may be listed in a number of ways, the most common being AWG (American Wire Gauge)(e.g. 16 AWG), Cross sectional area in square mm (e.g. 1 sq mm) or strand and diameter count (e.g. 32/0.2).

If buying new wire, the size will be listed on the reel or packet.

Many wires are now printed into the insulation with this information repeated along the length. Insulation diameter is important for the most reliable crimps as it affects how the rear of the crimp grips the wire, however as long as you use standard wires, then this should not give you a significant issue.

Step 3: Choosing the Crimp Terminal

Now you know what wire size you have, you will also need to work out what you need to connect to. There are many, many variations of crimp, but there are a handful of very common ones.

Pre-Insulated Terminals

If using pre-insulated terminals have a heat sleeve to grip the wire insulation.

All terminals are sold with a defined wire size range- this should be listed on the packet, but if not and you are using pre-insulated parts you can tell by the colour of the sleeve.

The generally adopted standard is:

- Red Insulation: 0.5-1.5mm2 / 22-16 AWG

- Blue Insulation: 1.5-2.5mm2 / 16-14 AWG

- Yellow Insulation: 4.0-6.0mm2 / 12-10 AWG

There are other colours around, but you are unlikely to come across these unless you are doing industrial, aerospace or military work.

Step 4: The Crimping Process

Step 1

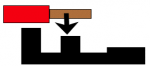

Take the wire you want to crimp and strip off about 4 mm from the end. You basically want to strip off enough insulation so that the exposed wire rests in the wire channel (the smaller second one) and the insulation rests in the insulation channel (the larger first one).

The wire should fit into the channels like the illustration shows.

Step 2

On many tools there will be two different "levels" on the tooth of the tool. This makes sure that the insulation channel has a big crimp than the wire channel, since the stripped wire has a smaller diameter than the insulation.

The larger side of the crimp ‘tooth’ should be where the insulation channel fits. Sorry for the blurry picture, but you can make it out, the pin is sitting in the groove with the ‘tabs’ facing into the groove. It is placed so that when the crimp tool is squeezed the tabs bend inwards and create a "heart" shape.

Step 3

If you apply light pressure to the tool at this point the crimp pin will slide up into the groove and be held in place.

At this point you can put the striped end of the wire through the hole that is made by the crimp tool and the insulation channel as shown in the picture.

Do your best to make sure the insulation channel only covers the insulation and the wire channel covers only the wire.

Apply firm pressure to the tool and it should perfectly bend the crimp tabs inwards so that they "bite" into the wire and insulation and form a solid contact.

Step 4

It should look something like this. You can see in the picture how the wire channel tabs bend inwards and bite into the insulation.

References

- http://www.molex.com/pdm_docs/ats/TM-640160065.pdf

- https://www.thomasnet.com/articles/machinery-tools-supplies/types-of-crimpers

- https://www.burndy.com/docs/default-source/PDF's/crimp-booklet_finalforprint_07162013.pdf?sfvrsn=0

- http://www-public.tnb.com/shared/inst/ta01977-tb2.pdf

- http://www.mouser.com/ds/2/276/640031200-588377.pdf

- https://www.youtube.com/watch?v=_ClY1pssIQs - Crimping Made Easy-Do watch

- https://www.youtube.com/watch?v=nEjbFngw6DY

If you are done reading this page, you can go back to Mechanical Subsystem.