Modeling of Sensors in Simulink

Contents

- 1 What is a sensor?

- 2 How can one model sensor in general, they are quite different in nature?

- 3 Why model a sensor in control law design?

- 4 Which characteristics will be modeled?

- 5 Will the above model would be enough for control law design?

- 6 How to get the data for sensor characteristics?

- 7 References

What is a sensor?

Sensors convert a physical phenomenon into electrical output. For example - temperature sensor (LM35) converts thermal energy into a change in voltage. Accelerometer converts acceleration into change in capacitance. Pressure sensor (piezo-resistive) converts changes in pressure into change in resistance. The changes in resistance or capacitance can be further converted into voltage. In general, the output of sensors of interest to us is in Voltage form.

How can one model sensor in general, they are quite different in nature?

Yes, you are absolutely right. The physics of all the sensor would be quite different for each sensor. The measurand (phenomena that you are interested in measuring) would be different. The method for measuring same phenomena could be different. For example temperature can be measured by LM35, thermocouple, thermistor, thermodiode etc.

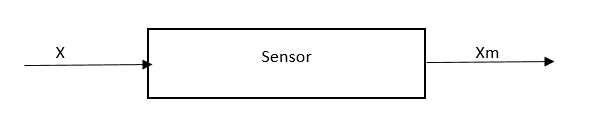

For a moment, forget about the internal structure of sensors. Consider the sensor as a black-box and it is measuring a physical quantity (say X) and giving output in electrical form, but since this measurement would be calibrated in the physical quantity again (say Xm , here m stands for measured ).

The internal design of each sensor is completely different and we are not going to model it. We will model only the part by which Xm differs from X, depending upon some common characteristic of sensors.

Why model a sensor in control law design?

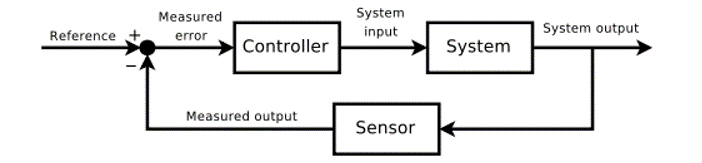

Take a typical closed loop control block, as shown in the figure below.

In this block, the sensor is used to measure system output and it sends the measured output to the controller. The actual output and measured output would not be same as sensor would have inherent noise. To account for these difference, we need to model the sensor.

Which characteristics will be modeled?

Some basic characteristics are: [1]

- Bias: Due to temperature dependence or manufacturing defect the output is not zero at zero input. This is known as bias.

- Noise: Signals which can't be measured are known as noise.

Will the above model would be enough for control law design?

For a preliminary model and for most practical purposes, this would be enough. However, one can dig into the physics of the particular sensor, write transfer function for each of the details, to get some more characteristics such as lag etc. [2]

One can also think about what causes error in the actual value and measured values. For example, mounting of the sensor improperly would produce erroneous result. Change of temperature or surrounding electric/magnetic field can be sometimes problematic. These can be incorporated in the model to make it more accurate.

How to get the data for sensor characteristics?

One can get these data from the sensor datasheet. You can get the datasheet from the supplier site of the sensor or else Google the model number and type of sensor. Read only the datasheet from the manufacturer and make sure that your model is the same as the model in the datasheet. Do not underestimate the reading of datasheet, it takes quite lot of effort to understand it properly. Sometimes the units of a parameter in the datasheet will help in understanding it.

If you are done reading this page, you can go back to Attitude Determination and Control Subsystem

References

- ↑ Sensors – the first chain in the measurement chain by Kim R. Fowler and John L. Schmalzel.

- ↑ A simple MEMS gyro model using MATLAB / Simulink: https://www.youtube.com/watch?v=P1OEoA70YJo