Passive Thermal Control System

Passive thermal control systems involve no mechanical moving parts or fluids. There is no power consumption which ensures its low mass and cost. It is highly reliable due to its design simplicity, implementation and testing. The only drawback of PTCS is its low heat transport capability except for heat pipes when compared with ATCS.

PTCS includes the following components:

Contents

Thermal Insulations

Introduction

Thermal insulations consist of low thermal conductivity materials combined to achieve an even lower system thermal conductivity. In conventional fiber-, powder-, and flake-type insulations, the solid material is finely dispersed throughout an air space. Such systems are characterized by an effective thermal conductivity, which depends on the thermal conductivity and surface radiative properties of the solid material, as well as the nature and volumetric fraction of the air or void space. A special parameter of the system is its bulk density (solid mass/total volume), which depends strongly on the manner in which the material is packed. If small voids or hollow spaces are formed by bonding or fusing portions of the solid material, a rigid matrix is created. When these spaces are sealed from each other, the system is referred to as a cellular insulation. Examples of such rigid insulations are foamed systems, particularly those made from plastic and glass materials. Reflective insulations are composed of multilayered, parallel, thin sheets or foils of high reflectivity, which are spaced to reflect radiant energy back to its source. The spacing between the foils is designed to restrict the motion of air, and in high-performance insulations, the space is evacuated. In all types of insulation, evacuation of the air in the void space will reduce the effective thermal conductivity of the system. It is important to recognize that heat transfer through any of these insulation systems may include several modes: conduction through the solid materials; conduction or convection through the air in the void spaces; and radiation exchange between the surfaces of the solid matrix. The effective thermal conductivity accounts for all of these processes.

Multi Layer Insulation (MLI)

Multilayer Insulation (MLI) is used to minimize temperature gradients throughout the spacecraft and to control heat transfer rates. MLI blankets prevent both excessive heat loss from a component and excessive heating from environmental fluxes, rocket plumes, and other sources. Most spacecraft flown today are covered with MLI blankets, with cutouts provided for areas where radiators reject internally generated waste heat. Single-layer radiation barriers are sometimes used in place of MLI where less thermal insulation is required, since they are lighter and cheap to manufacture.

In practice, simply increasing the number of layers past a certain value will not improve performance. As the no. of layers increases, radiative heat transfer becomes small compared with conductive “shorts” between layers and other losses. Taking all these factors into account, about 25 layers usually suffice to obtain a minimum overall conductance value.

Working of MLI

Lets understand this with an example.

Imagine a square meter of a surface in outer space, at 400 K, with an emissivity of 1, facing away from the sun or other heat sources. From the Stefan–Boltzmann law, this surface will radiate 1452 watts. Now imagine placing a thin (but opaque) layer 1 cm away from the plate, thermally insulated from it, and also with an emissivity of 1. This new layer will cool until it is radiating 726 watts from each side, at which point everything is in balance. The new layer receives 1452 watts from the original plate. 726 watts is radiated back to the original plate, and 726 watts to space. The original surface still radiates 1452 watts, but gets 726 back from the new layers, for a net loss of 726 watts. So overall, the radiation losses have been reduced by half by adding the additional layer.

MLI is composed of multiple layers of low-emittance films.

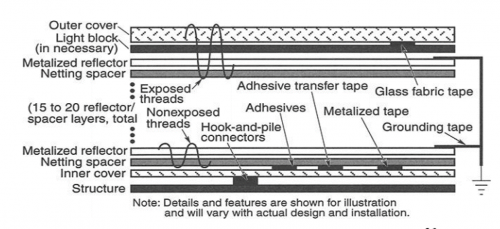

The simplest MLI construction is a layered blanket assembled from thin embossed Mylar sheets, each with a vacuum-deposited aluminum finish on one side. As a result of the embossing, the sheets touch at only a few points, and conductive heat paths between layers are thus minimized. The layers are aluminized on one side only so that the Mylar can act somewhat as a low-conductivity spacer. Higher-performance construction is composed of Mylar film metalized (with aluminum or gold) on both surfaces with silk or Dacron net as the low-conductance spacers.

Heat transfer through MLI is a combination of radiation, solid conduction, and, under atmospheric conditions, gaseous conduction. These forms of heat transfer are minimized in different ways. Radiative heat transfer is minimized by interposing as many enclosing reflective surfaces (metalized sheets) as is practical between the object being insulated and its surroundings. Solid-conduction heat transfer is minimized by keeping the density of the low-conductance spacers between the reflective surfaces as low as possible and making the blanket "fluffy" to minimize contact between layers.

Because the heat transfer mechanisms operate simultaneously and interact with each other, a useful technique is to refer to either an apparent thermal conductivity, , or an effective emittance, ϵ*, through the blanket. Both values can be derived experimentally during steady-state heat transfer.

In theory, for highly evacuated MLI systems, the emittance ϵ for a blanket of N non-contacting layers of emissivities ϵ1 and ϵ2 on opposite sides is computed as:

In satellite applications, the MLI will be full of air at launch time. As the rocket ascends, this air must be able to escape without damaging the blanket. This may require holes or perforations in the layers, even though this reduces their effectiveness.

MLI blankets are constructed with sewing technology. The layers are cut, stacked on top of each other, and sewn together at the edges. Seams and gaps in the insulation are responsible for most of the heat leakage through MLI blankets. A new method is being developed to use polyetheretherketone (PEEK) tag pins (similar to plastic hooks used to attach price tags to garments) to fix the film layers in place instead of sewing to improve the thermal performance. Traditionally, MLI blankets are sewn together; the multi-layered blanket being held together by stitches. However, any kind of hole that punches through the layers tends to degrade the overall thermal performance of the blanket. Another method, of using tag-pins - the small nylon "I" looking pins that are used to hook price tags to clothes in stores - to fix the layers in place, has been mentioned in the literature, see paper by R. Hatakenaka, here). That way you don't need to punch as many holes as when you are sewing, and tagging - a few inches between tags - is faster and less error-prone than sewing around the whole perimeter of the blanket. Moreover, the tag-pins allow you to fasten the layers together without compressing them, which reduces stress around the holes. Lastly, the blankets tend to contract in the direction of sewing which might lead them to be to small if not oversized properly.

In some applications the insulating layers must be grounded, so they cannot build up a charge and arc, causing radio interference. Spacecraft also may use MLI as a first line of defense against dust impacts.

Surface Coatings and Paints

The Space Station has a variety of surface finishes because of the variance in thermal requirements from location to location. Thermal coatings and paints must be compatible with the environment and must be resistant to radiation and atomic oxygen that they will be constantly exposed to.

Different types of finishes are used to provide various degrees of thermal control for on-board equipment. Using coatings and paints with different emissivity and absorptivity with different characteristics allows the region or component to either be “warmed” or “cooled” as required. An example of this are radiators that use high emissivity and low absorptivity coatings to help radiate excess heat to space.

Phase Change Materials

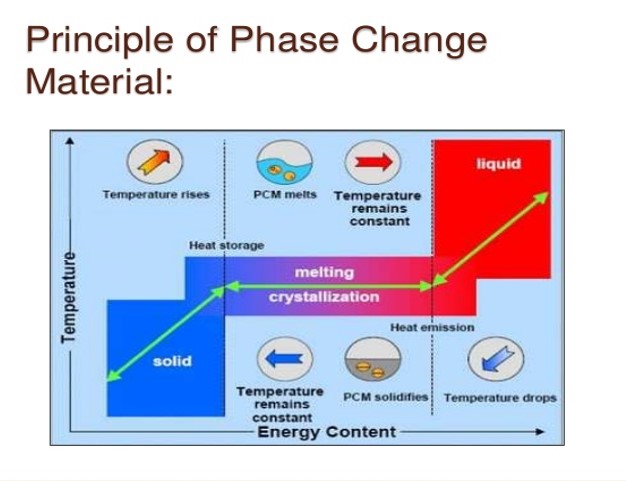

The proposed technology will enable efficient thermal control by maintaining a constant temperature heat sink or heat source for a range of electronic components in rapidly changing thermal environments. The PCM panel is being designed as a lightweight and flexible component, yet having high thermal capacity, requiring less mass and volume than currently used carbon-fiber and aluminum honeycomb composite panels.

Ex: PCM briefing: Managing heat in low-orbit satellites

Roccor LLC of Longmont, Colo., is using phase change material in a device designed to manage internal heat in low-orbit satellites. A product with paraffin wax inside a flat structure i used. When the spacecraft is hot, it dumps heat into that paraffin wax and turns that into a liquid — basically a store of energy. The heat is later released into the satellite to keep temperatures stable.

PCM is one of the developing areas in efficient passive thermal control systems which acts as both a heat sink or a heat source based on the demand of the system.

If you are done reading this page, you can go back to Mechanical Subsystem

References

- http://pages.erau.edu/~ericksol/projects/issa/thermal.html

- https://en.wikipedia.org/wiki/Spacecraft_thermal_control

- Spacecraft Thermal Control Handbook Volume I: Fundamental Technologies, David G. Gilmore

- http://www.esa.int/Our_Activities/Space_Engineering_Technology/Thermal_Control